Category: WATER CONTROL VALVE

working principle:

When filled with water, the float rises and drives the valve disc to close, stopping exhaust. When the water in the pipe is transported normally, if a small amount of air accumulates in the valve to a considerable extent, the water level in the valve will drop, and the float will drop accordingly. At this time, the air will be discharged from the small hole. When the water pump stops, the water in the pipe is empty or negative pressure is generated in the pipe. At this time, the valve flap opens quickly to suck in air to ensure the safety of the pipeline.

Features:

1. When the empty pipeline system is filled with water, a large amount of air can be discharged

2. It can continuously discharge trace amounts of air accumulated in the piping system through small holes;

3. When the pipeline is empty, a large amount of air can be sucked in from the atmosphere to prevent the pipeline from being broken or deformed.

●Sophisticated and advanced mechanical design and strong floating ball can prevent damage from sudden water hammer.

● Before the water level rises enough to push the float to seal the large exhaust hole; even when the flow rate of compressed air reaches the speed of sound, the float can still stay at the bottom position.

●There are no arms or levers to prevent vibration and falling off problems.

●There is a stainless steel sleeve on the outside of the float to ensure that the float slides in the set guide rail.

●The bottom rubber anti-collision pad has the function of protecting the floating ball from collision during descent. Under negative pressure, through a sufficient number of holes carefully designed, rapid drainage and air suction functions can be achieved.

●The upper filter, as an optional part, has the function of safety protection and preventing insects or birds from entering.

●The outside of the valve body is coated with epoxy resin to achieve a longer service life.

Technical Parameters:

Nominal diameter: DN50-DN200

Nominal pressure: 1.0Mpa, 1.6Mpa, 2.5Mpa

Applicable temperature: 0-80C.

Applicable medium: water

Manufacturing standards: Comply with GJ/T 217, BS EN 1074--3 and AWWA C512.

Flange standard: In line with GB/T 17241.6, BS EN 1092 and BS EN 558 and ANSI specifications.

Main material

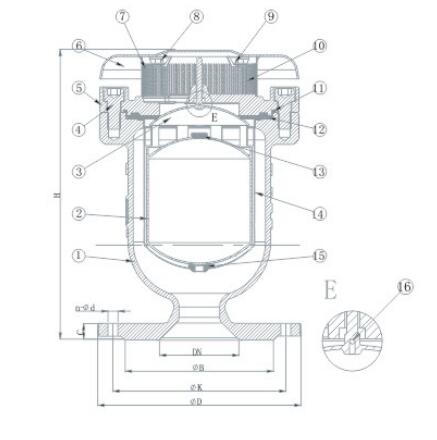

No.

Part Name

Material

1

valve body

Ductile iron

2

Float

Stainless steel

3

Sealing cover

Stainless steel

4

Hexagon socket bolts

Carbon steel/stainless steel

5

cap

Ductile iron

6

Dust cover

Carbon steel

7

Dust net

Stainless steel

8

Hex bolts

Carbon steel/stainless steel

9

Flat pad

Stainless steel

10

pillar

aluminum

11

O-ring

rubber

12

Center cavity gasket

rubber

13

Vent gasket

rubber

14

Outer sleeve

Stainless steel

15

Anti-collision cover

rubber

16

Vent

Stainless steel